TLDR¶

• Core Points: Researchers replace metal or plastic gears with controlled liquid flows to transfer motion between rotating cylinders; experiments use a viscous water–glycerol mixture to convey torque without solid gears.

• Main Content: The study, published January 13 in Physical Review Letters, demonstrates how fluid dynamics can generate coordinated motion between immersed cylinders, offering a new paradigm for transmission of mechanical power.

• Key Insights: Liquid-based gear systems could redefine efficiency, wear, and design flexibility, highlighting how fluid mechanics may complement or replace traditional gear trains in specific contexts.

• Considerations: Practical implementation requires precise control of viscosity, flow stability, sealing, and scalability; energy losses and maintenance in fluid gear systems must be assessed.

• Recommended Actions: Encourage cross-disciplinary research combining fluid dynamics, materials science, and mechanical engineering; pursue experimental prototypes and simulations to map performance envelopes.

Content Overview¶

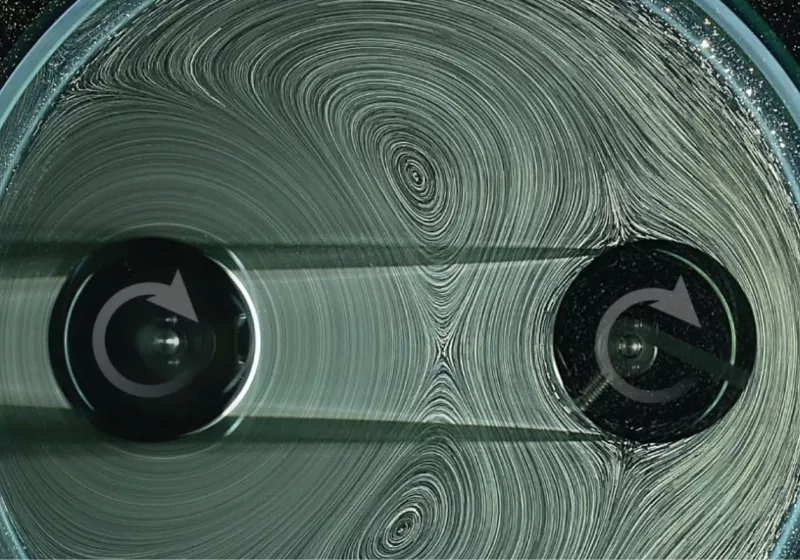

The article reports on a novel approach to mechanical power transmission that challenges the long-standing dominance of solid gears. In a study published January 13 in Physical Review Letters, physicists at New York University replaced conventional cogs—typically made from metal or plastic—with carefully controlled flows of liquid. In the experimental setup, two cylinders were submerged in a viscous liquid mixture of water and glycerol. When one cylinder was rotated, the flows it created induced motion in the second cylinder, effectively transferring rotation without a traditional gear interface. This concept introduces the possibility of leveraging fluid dynamics to perform mechanical work, potentially offering different advantages and trade-offs compared with solid gears. The work sits at the intersection of fluid mechanics and mechanical engineering and could point toward a broader class of devices in which liquids perform rapid, configurable power transmission tasks.

In-Depth Analysis¶

The central idea behind liquid gears is to exploit viscous coupling and hydrodynamic forces to transmit torque between moving bodies immersed in a liquid. In the NYU experiments, two cylinders act as the primary actors in a fluid environment. When the first cylinder rotates, it creates a complex pattern of circulating flows in the glycerol–water mixture. The second cylinder, immersed in the same fluid, experiences these flows and begins to rotate as a consequence of fluid drag and pressure fields generated by the first cylinder’s motion. Importantly, there is no rigid teeth meshing between components; instead, the interaction arises entirely from the physics of viscous liquid flow and the resulting momentum exchange.

Several key physical principles underlie this approach:

- Viscous coupling: The liquid’s viscosity translates motion from one object to another through shear forces in the fluid layer between surfaces. The efficiency of this transfer depends critically on fluid viscosity, interfacial geometry, and the relative motion of the cylinders.

- Hydrodynamic torques: The rotating cylinder generates circumferential and axial flow patterns, producing torques on nearby bodies. The orientation, distance, and surface characteristics of the second cylinder affect how effectively it picks up rotation.

- Flow stability and laminar regime: In the studied setup, the regime is largely laminar due to the high viscosity of the mixture, which helps maintain predictable flow patterns. Turbulence or flow instabilities could complicate transmission in other configurations.

- Energy losses: Unlike solid gears that transmit power through contact mechanics and enamel tooth engagement, liquid gears experience continuous viscous dissipation. Frictional losses manifest as heat within the liquid, which could influence efficiency and thermal management strategies.

The experimental results demonstrate a qualitative proof of concept: rotation of one element induces motion in a second, leveraging the liquid medium as the transmission medium. Quantitative assessments—such as torque transfer efficiency, the range of angular velocities, and the sensitivity to viscosity—would be essential to map the practical viability of liquid gears. These metrics would help determine optimal fluid formulations, tube or channel geometries, and operating conditions for various power transmission tasks.

From a broader perspective, this approach invites a reexamination of the traditional hierarchy of mechanical components. Gears have persisted for millennia because they provide robust, scalable, and compact means of transmitting torque with predictable gear ratios. Liquid gears do not inherently provide fixed gear ratios, but they can be tuned through geometry, viscosity, and boundary conditions to achieve defined relationships between driving and driven elements. In certain contexts—where contact between solid parts is undesirable, or where precise lubrication or corrosion resistance is required—fluid-based transmission could offer unique advantages.

The researchers’ work also raises questions about manufacturability and integration. Liquid-driven systems would demand sealed, maintenance-friendly housings to control the fluid environment and prevent leakage. The selection of liquid mixtures must balance viscosity, safety, environmental impact, and compatibility with other materials in the device. Moreover, controlling the exact speed and torque output would require advanced feedback mechanisms and possibly active flow control techniques to stabilize performance under varying load conditions.

Another consideration is the scalability of liquid gears. In micro- to meso-scale devices, fluid transmission could exploit high viscous forces within compact channels, enabling compact, low-wear mechanisms for specialized applications. For larger systems, cumulative viscous losses and heat generation might become limiting factors, necessitating clever thermal management and energy recovery strategies.

The study fits within a broader trend of exploring non-traditional transmission modes in mechanical engineering, such as magnetically coupled components, fluidic circuits, and soft robotics-inspired devices. By expanding the palette of available power-transmission mechanisms, researchers aim to tailor devices to niche requirements—where conventional solid gears may be less suitable due to wear, lubrication needs, noise, or contamination concerns.

Although the NYU study highlights a compelling principle, several critical questions remain for the field:

- How does one tune the torque-speed characteristics to achieve specific gear ratios or motion profiles with liquids?

- What are the long-term stability and reliability considerations for liquid gears under repetitive cycling and varying temperatures?

- Can this concept be integrated with existing mechanical systems to complement or replace traditional gears in targeted use cases?

- What are the safety, environmental, and cost implications of employing viscous liquid media at scale?

Future research directions will likely include systematic experiments that vary fluid viscosity, cylinder spacing, and surface finishes to chart the parameter space for efficient liquid-to-solid motion transfer. Computational fluid dynamics (CFD) simulations will be essential, enabling researchers to predict flow fields, optimize geometries, and explore non-Newtonian fluids that might offer favorable performance traits. Additionally, hybrid designs could emerge, wherein a modest mechanical framework is supplemented by controlled liquid coupling to achieve tunable or adaptive power transmission.

The reported work also serves as an educational benchmark, illustrating how fundamental physics—specifically, viscous flow and hydrodynamic interaction—can produce counterintuitive results. It underscores the value of interdisciplinary collaboration, bringing together physicists and mechanical engineers to rethink foundational components. While still at an exploratory stage, the concept of liquid gears adds a new dimension to the study of motion transmission and could catalyze innovative applications across microfluidics, soft robotics, aerospace, and industrial machinery where conventional gears face limitations.

*圖片來源:Unsplash*

Perspectives and Impact¶

The potential impact of liquid gears extends beyond a mere curiosity. If refined and scaled, they could offer:

- Reduced wear and maintenance: Liquids do not experience tooth fatigue or surface pitting, potentially lowering wear-related maintenance demands in certain environments. However, liquid erosion, corrosion, or contamination could pose new challenges.

- Fluidic integration: Devices could leverage existing fluid-handling infrastructure, enabling compact, integrated systems where lubrication and cooling are naturally achieved through the working fluid.

- Noise reduction: Absence of interlocking teeth might translate to quieter operation, which is advantageous in precision instrumentation or consumer products seeking reduced acoustic signatures.

- Tunable performance: By adjusting viscosity, temperature, or channel geometry, operators could dynamically modulate transmission characteristics, enabling adaptive machinery that responds to load changes.

On the flip side, the technology faces substantive hurdles:

- Efficiency and heat management: Viscous losses convert mechanical energy into heat, which could degrade efficiency, particularly at higher power levels. Effective cooling strategies would be indispensable.

- Sealing and reliability: Maintaining a leak-free liquid environment under rotational motion is nontrivial, especially in rugged or remote settings.

- Material compatibility: The liquid medium must be compatible with seals, housings, and any components in contact with the fluid to avoid degradation.

- Operational range: The attainable torque, speed, and gear-like ratio ranges may be more restricted than with rigid gear trains, at least in early-stage implementations.

Future impact will hinge on whether researchers can translate this concept into devices that solve real engineering problems more effectively than existing technologies. Possible applications could emerge in micro-robotic systems where compact, low-wear transmission is beneficial, or in environments where lubrication is difficult or where a sealed liquid medium doubles as a coolant. The concept might also inspire hybrid systems that blend traditional gears with liquid-based couplings to achieve tailored performance envelopes.

The broader scientific takeaway is that revisiting established mechanical paradigms with fresh physical perspectives can yield innovative approaches. The liquid gear concept demonstrates that not all power transmission must rely on rigid contact interfaces. By harnessing the physics of viscous flows, researchers can conceive alternative pathways for transferring motion, with potential implications for design philosophy in mechanical engineering education and industry practice.

Researchers are expected to continue refining the theoretical framework and pursuing experimental demonstrations that quantify performance across a wider range of conditions. Collaboration with materials scientists could lead to novel fluids or fluid-solid interfaces that optimize energy transfer while mitigating losses. As computational models grow more accurate, simulations will play an increasingly important role in guiding experimental work and accelerating the transition from concept to applied technology.

In sum, liquid gears constitute a provocative challenge to 5,000 years of mechanical engineering tradition. They do not merely replace teeth with liquid; they invite a reevaluation of how motion and power can be conveyed, emphasizing the rich potential of fluid dynamics to complement and augment solid-state mechanisms in the ongoing evolution of engineering design.

Key Takeaways¶

Main Points:

– Liquid gears use controlled flows of viscous fluid to transfer motion between immersed cylinders, avoiding solid interlocking teeth.

– The concept leverages viscous coupling and hydrodynamic torques to produce rotational transmission.

– Practical deployment will require extensive work on efficiency, sealing, scalability, and control systems.

Areas of Concern:

– Energy losses and heat generation in viscous transmission.

– Reliability and sealing challenges in rotating liquid environments.

– Limited initial data on torque, speed ranges, and long-term performance.

Summary and Recommendations¶

The NYU study presents a provocative proof-of-concept that liquid-based transmission can mediate motion between rotating components through carefully managed fluid dynamics. While the experiments demonstrate feasibility in a controlled setup using a viscous water–glycerol mixture, substantial work remains to translate this idea into practical engineering solutions. Critical avenues include optimizing fluid properties and geometries to maximize torque transfer while minimizing energy losses, developing reliable seals and containment strategies, and exploring scalable designs that can operate across diverse power ranges. Computational modeling, coupled with iterative prototyping, will be essential to map the performance envelopes and identify viable applications. If these challenges can be addressed, liquid gears may emerge as a complementary or alternative transmission technology for niche applications where traditional gears face limitations, potentially reshaping how engineers conceive motion transmission in the decades to come.

References¶

- Original: https://www.techspot.com/news/110953-liquid-gears-challenge-5000-years-engineering-tradition.html

- Additional reading:

- Fundamental study of viscous coupling in fluid-structure interactions (peer-reviewed sources on hydrodynamic torque transfer)

- Reviews on non-traditional transmission systems and soft robotics where fluidic mechanisms are explored for actuation and motion transfer

- Materials science perspectives on compatible fluids and seal technologies for fluid-based mechanical interfaces

Forbidden:

– No thinking process or “Thinking…” markers

– Article must start with “## TLDR”

Ensure content is original and professional.

*圖片來源:Unsplash*